PARESH ENGINEERING COMPANY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PARESH ENGINEERING COMPANY

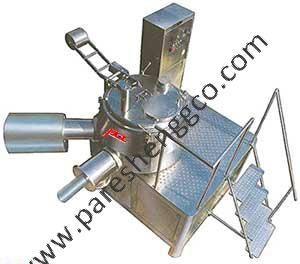

Planetory Mixer

Machine Description:

Planetory Mixer is a modern heavy duty mixer designed specially for uniform Mixing by planetary movement of beater(agitator). Detachable cylindrical bowl with flat / hemispherical bottom of suitable dimension and Batter / Dough Hook / Wire Whip Cage Type blade is constructed out of SS-316 / SS-304 / MS Material. Detachable agitator is bolted / fitted manually by simple twisting action.

Drive:

The Blade is driven by Single / Two / Variable Speed electric motor with suitable gearbox. Planetary disc is rotated clockwise and blade in an anti-clockwise direction on its own axis with suitable rpm. If variable speed is required, AC frequency unit will also be provided.

Stand:

The whole drive assembly is rested on MS column with heavy base frame and mixing bowl is fixed with MS fabricated bracket. The bowl with bracket is raised/down manually by handle in respect of small machines and motorized or hydraulic system is provided for lifting / lowering drive head with agitator in respect of heavy duty machines.

Special Features:

• Bowl will be jacketed for heating or cooling.

• Mixer can be designed to operate under vacuum to avoid air entrapment in product during mixing.

• The bowl will be provided with caster wheels for easy movements for cleaning, washing and handling mixed materials.

• Single blade / double blades and a Teflon edged scraper will be provided for scrapping the material from the sidewall.

• GMP / NON-GMP / FLP construction

Contradrive Agitator

|

Mighty Mixer

By combining single planetary blade with high speed disperser, Mighty mix can handle materials over an enormous range of viscosity and accomplish the work of two mixers of your process line. The planetary blade continuously sweeps the side wall and forcing material to the center of the vessel and high shear disperser Teflon side-scraper is provided for scrapping the material from side-wall. You can begin the mixing process with low viscosity, non-flowable pasty end product. Dispersion liquids ad solids, the Mighty mix can complete the mixing process faster and more thoroughly and efficiently due to high shear mixing action.

Once the mix cycle is complete lift the head hydraulically along with the blade and roll the vessel to a Discharge System work by hydraulic pressure system where the end product will be discharged to a secondary mix vessel or directly to metering /dispensing/packing equipment. The process enhances operators safety and reduces the risk of contamination and also save time and significantly reduces production cost.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.